In some cases, a continuous gap of minimum 300 mm width is left between two adjacent floor sections. For example, pour strips are often used in large floor structures to separate different floor sections to be placed in the same pour. In some cases, special procedures and construction sequences are required to minimize the development of cracks in the concrete due to structural or architectural restraints or temperature changes.

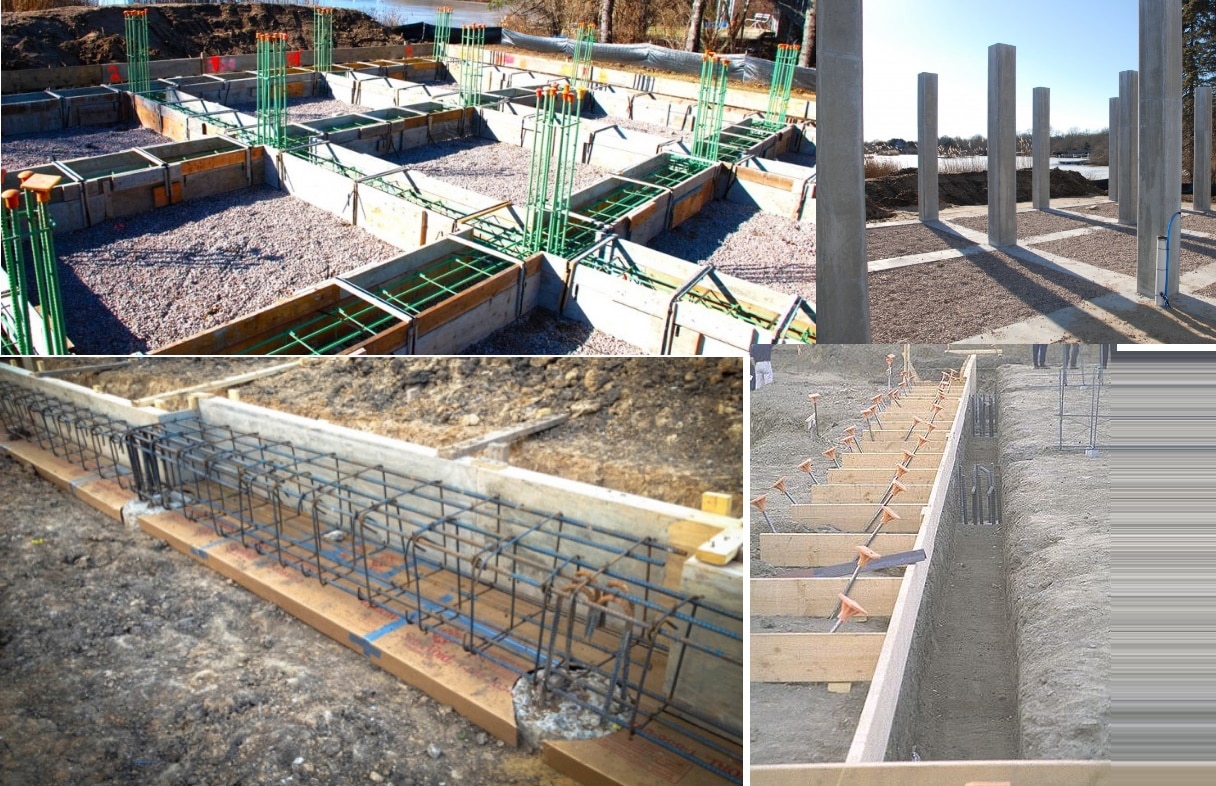

The proper amount of concrete must be placed such that the slab thickness, beam sizes, and wall and column dimensions are in accordance with the structural drawings. Special concrete placement procedures, such as placement by pumps or wheelbarrows site batching or cylinder testing by an independent testing agency, must be carried out in accordance with the structural drawings and specifications. The concrete ready-mix company will supply concrete based on the concrete strengths specified on the structural drawings and the mix designs that meet the specific climate and workability requirements of the site. Rebar clearances must be properly shown on the structural drawings in order for the rebar placer to accurately place bar supports to ensure proper bar position. Their role is to interpret structural drawings along with the detail sheets and then place the reinforcing steel as precisely as possible. Placement of the reinforcing steel is carried out by rebar placers. In some cases, rebars are cut and bent at the construction site. Once the reinforcement has been detailed and cut in the shop, it is delivered to the site in bundles. On the other hand, a bid below fair market value may lead to problems during construction, usually in the form of numerous requirements for extra payments by the contractor in trying to recover losses caused by the low bid.

On the one hand, the owner may feel that (s)he is overpaying if the highest bid is accepted. This is an unfavourable situation for the owner, who ultimately pays for the construction. In general, a variation in the bid price of over 10% is considerable, as it leaves the owner confused about the proper market price for the project. When drawings are ambiguous, there could be large variations in price between competitive bids submitted by different contractors in the bidding process. The drawings must be clear and concise and without ambiguities. Based on these drawings, the estimator should be able to estimate the quantity of materials and also the extent of complexity in the construction procedures, any unusual complications associated with the erection, formwork, and shoring, etc. This estimate is based on structural drawings and specifications that are issued for construction. Once the structural drawings have been completed, the contractor produces an estimate of the concrete and reinforcing steel quantities, as well as the amount of formwork and shoring.

0 kommentar(er)

0 kommentar(er)